3D Printer : What Is It, How Does It Work And What Is The Use Of 3D Technology

Has your coffee machine broken again? Instead of sending it to the manufacturer and possibly waiting two weeks for the repaired appliance or buying a new one, you now have a third option. Why not print out the broken part at home and use it yourself? Music of the future? Not at all.if you already own a 3D printer, you will not be able to use SketchUp.

The history of 3D printing

The technology of 3D printing is certainly not entirely new, as it has been used since the 1980s, especially in the aircraft and automotive industries.

Custom-fit components are manufactured here. However, these printers were enormous, making them unusable for home use.

The Solidoodle company, whose founder Sam Cervantes has made it his mission since 2011 to “make 3D printers available to creative people all over the world”, can help here.

The market is booming now that 3D printer no longer have the dimensions of a small car and do not cost as much as the car just mentioned.

Solidoodle developed a printer of the same name, which can easily be placed on a home desk and costs as much as an inkjet printer in the upper price range.

These devices are available for 499 US dollars, but there are still significant compromises in terms of quality. The size of the objects that can be printed is also minimal. This is how the entry-level device manages object sizes of 4x4x4 inches.

For $50, you can get a device that can print objects as large as 6x6x6 inches, and if you’re willing to pay another $50 more, you can get a printer that’s protected with an outer case, but the size doesn’t change at this price point of the objects.

To be able to print something with these devices, you need a file from the desired object that contains a detailed 3D model of the thing.

You don’t need to be a graphic designer or have programming knowledge to create one. You don’t have to buy expensive software either because the SketchUp program allows you to design your own 3D models. However, if you cannot do this as desired, there are other options.

There are companies you can send your immature 3D models to, and they will give you the finishing touches, then print them out for you and send your model to your home, not entirely free of charge, of course.

Fabberhouse, i.materialise, and Sculpteo are some of them.There are platforms such as Thingiverse or Shapeways where users can upload their models. These are then available for you to download.

There are now a large number of commercial 3D printer.

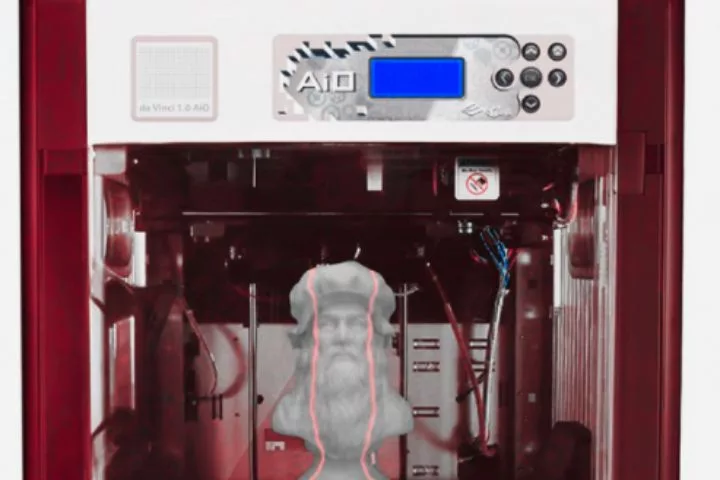

So there are “affordable” and ready-made 3D printer. No more kits for technology freaks but ready-to-use devices. XYZ Printing has brought a range of devices onto the market, leaving nothing to be desired, from entry-level models to professional instruments.

The Da Vinci Junior 1.0 with a single XY Printing extruder impresses with its compact design and safe operation. It is currently (December 2017) offered for an end customer price of €369.

The required filament cassettes cost between 19 and 29 euros per color. XYZ Printing already has printers with an integrated scanner to copy models directly 1:1.

But how do these 3D printers work?

There are various ways in which 3D printers produce the desired models. In the following, we will explain the most common ones in a little more detail:

Stereolithography

Detailed models with a smooth surface are made from synthetic resin. The synthetic resin is poured into a basin layer by layer, with each layer no thicker than a fraction of a millimeter, and exposed and cured with the help of a UV laser.

After one layer has been exposed and cured, the next is poured on top of it until the object has been printed.

The remaining, still liquid synthetic resin that is not used is too unstable to support the thing being produced, so a second so-called support material is needed, which is removed later.

Manufacturers of printers using this technique are 3D Systems and Objet. Objet also holds a patent for a process that uses translucent material and the so-called PolyJet process, which allows printing with several different materials simultaneously in a single operation.

Lasersintern

Plastic and metal are used in this process. A slider distributes the raw material used here in powder form again in layers on the worktop.Like in stereolithography, the material is selectively heated with a UV laser, and the granules fuse.

However, unlike stereolithography, the remaining powder is stable enough to serve as a support for the resulting model. It is brushed off after the process is complete and can be reused.

Models made with this technique often have a rough surface but are much more flexible and stable than other models. A specialist in this field is the company EOS.

3D printing

3D printing crosses laser sintering and traditional 2D printing with an inkjet printer. A multi-color printhead spreads colored ink on a thin layer of plaster-like powder.

A binder mixed with the ink allows only the printed areas to harden. The finished models are dipped in synthetic resin to ensure a smoother surface.

This technique also requires no support material, but the material is comparatively heavy and brittle. Z-Corporation holds the patent for this approach.

Fused Deposition Modeling

Molten plastic, also called a filament, is pressed out of a nozzle, which ‘draws’ the desired shape layer by layer. The plastic used in this procedure is the so-called ABS plastic.

For more professional processes of this type, some printers work with two nozzles simultaneously, so overhang models are also possible.

However, the individual layers are up to a quarter of a millimeter thick, so they are clearly recognizable in the finished objects.

Use of 3D technology shortly.

This may all sound futuristic enough for some of you. Just turn on the printer and print out a bottle opener, a clockwork, or even Neil Armstrong’s footprint that he left on the moon.

But the research goes a few steps further. The company Modern Meadow is working on a concept with which meat and leather can be printed without having to kill animals.

An alternative not only for people who do not eat meat for religious or ethical reasons but also the despised factory farming.

Live cells are used to produce synthetic meat. These are not just pipe dreams of the researchers, and the first synthetic chop has already been printed, cooked, and eaten. The company’s forecast is

But it’s not just the Modern Meadow company that isn’t satisfied with plastic model printouts, and medicine also senses a great opportunity here.

For example, a technique is being worked on to process human cells into tissue parts that will be used for clinical purposes shortly. This technology could revolutionize medicine.